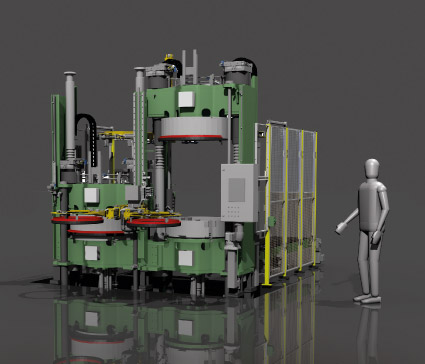

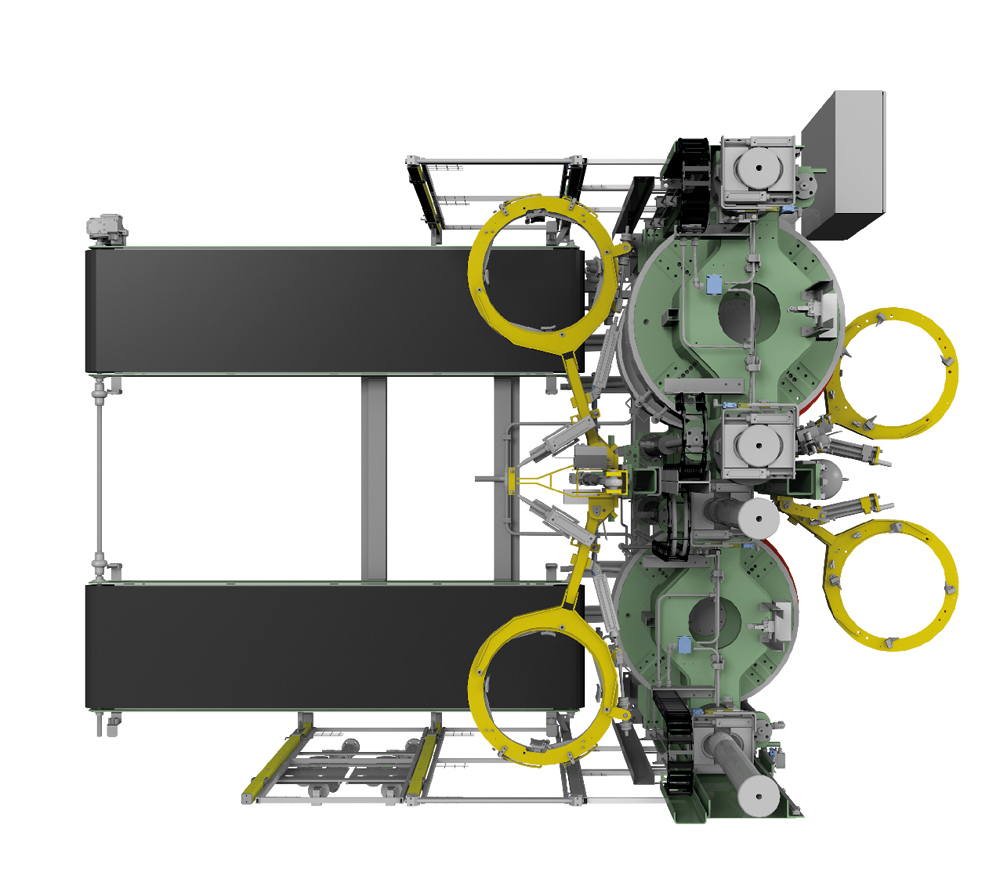

In order to cover the rapid growing demands of the 2-wheeler and scooter markets, HF adapted its proven column design for this press type to produce standard to high-end performance tires.

| Item Cavity control Max. closing force | Unit kN (t-force) | 36'' Curing Press common/independent 800 Max. closing force (t-force) (90) |

|---|---|---|

| Tire Parameters | ||

| Bead diameter | inch | 10-21 |

| Green tire outer diameter | mm (inch) | 610 (24) |

| Cured tire outer diameter | mm (inch) | 720 |

| Cured tire height | mm (inch) | 250 |

| Mold Container | ||

| Type of mold | 2-piece/segmented | |

| Max. outer diameter | mm (inch) | 889 (35) |

| Min./max. mold height | mm (inch) | 100-300 (3,9-11,8) |

| Heating Platen | ||

| Outer diameter | mm (inch) | 889 (35) |

| Center Mechanism | standing post (pit or pitless design) | |

| Green Tire Stand (single or multiple) |

hanging/shoulder type | |

| Pneumatics Hydraulic System from 1:1 to 1:6 (or more) |

||

| Heating System piping and manifold concept available various media available (steam/N2, steam/steam, hot water, etc.) |

customized to meet your requirements | |

| PLC Systems/Automation | main suppliers available | |

| Safety | according to local safety standards |