The function of the tread skiver is to cut strip profiles in start/stop modes. The cutting angle is 90° (top view) in running direction. The belt and knife carriage are driven by electric motor reducers. The cutting knife is cooled and lubricated by spraying water. Clamping devices are used as fixture for the strips.

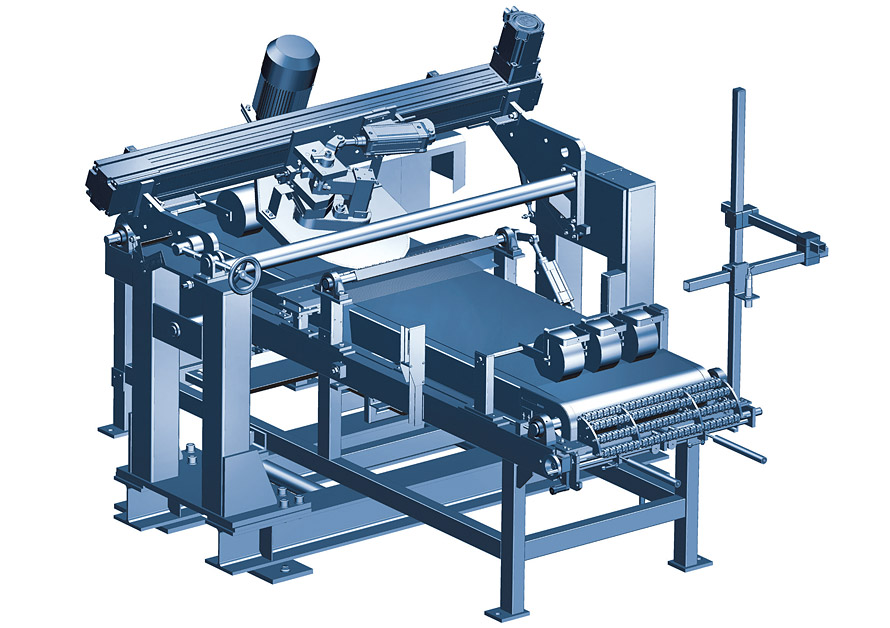

The skiver consists of a one-piece conveying table with a conveyor belt and a cutting assembly arranged on top.

The cutter belt of approx. 4000 mm length consists of a rubber belt, the upper side is supported by a slide plate. A static contact roll prevents the strips from slipping while advancing. The strips are positioned over a cutter bar at the position where the cut is carried out. At the belt conveyor inlet a roller basket with omni-directional rolls and adjustable centering rolls is installed.

| Description | Skiver 650 | Skiver 900 | |

|---|---|---|---|

| Line width | mm | 650 | 900 |

| Max. Tread length approx. | mm | 2300 | 4000 |

| Min. Tread length approx. | mm | 1500 | 2000 |

| Knife diameter | mm | 500 | 500 |

| Tread thickness | mm | 30 | 30 |

| Cutting angle to extrusion line | 90° | 70°-90° | |

| Cutting angle to tread | 20°-40° | 20°-40° | |

| Mechanical length tolerance | mm | ± 0,5 | ± 0,5 |

| Number of cuts | per minute | 26 | 18 |

The drive of the conveyor belt is equipped with a variable speed motor reducer; braking from high to extremely slow speed or even to a complete stop is therefore possible.

The cutting assembly consists of a base plate with two supports, a bridge bolted in between, the knife support and the cutter knife. The traverse motion of the knife is effected via a toothed belt driven by a variable speed motor reducer. The knife carriage lift is infinitely adjustable. The cutter knife is driven by an AC motor. The swiveling motion of the cutter knife from cutting position to the return position is performed by a pneumatic cylinder which is mounted in the knife support.

The pneumatic press-down bar with clamping lamellas holds the strips in position during the cutting process.

The spraying water device lubricates the cut with demineralized water. The required spray nozzles are fastened to the knife carriage. Machine parts which come into contact with the water are protected against corrosion, where possible they are manufactured from rust-free material. Water collectors and guard plates serve as spray water guards.

The protective housing of the skiver consists of a frame of sectional aluminum profiles and transparent plates. The housing has two access doors controlled by safety switches. The electrical equipment for the skiver with its variable speed motor reducers and the AC motor is included in the extrusion line’s electrical equipment.