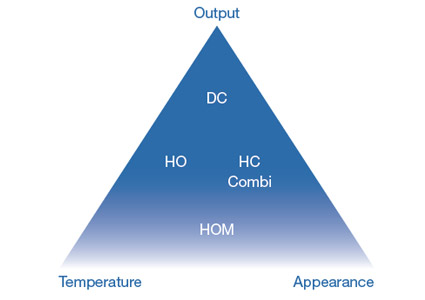

The choice of the correct screw depends on three main factors: Temperature, appearance and output. Maximizing one always influences the other two.

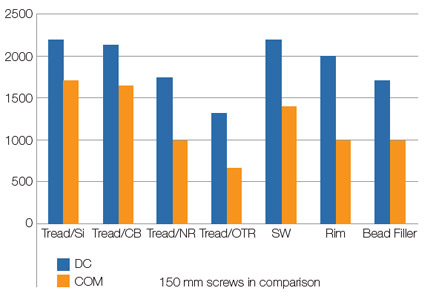

We have developed screws that are specialized for certain tasks. For example our Deep Cut (DC) screw has a high output performance and is perfect for the use with compounds that aren’t homogenization critical. A comparison of the different models and a side-by-side output analysis of DC and our all-purpose combi screw is shown below .

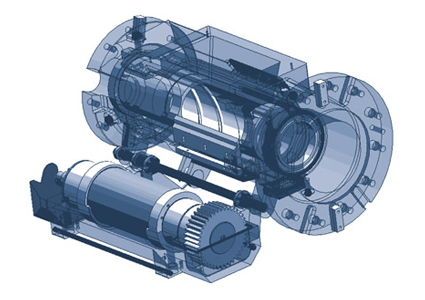

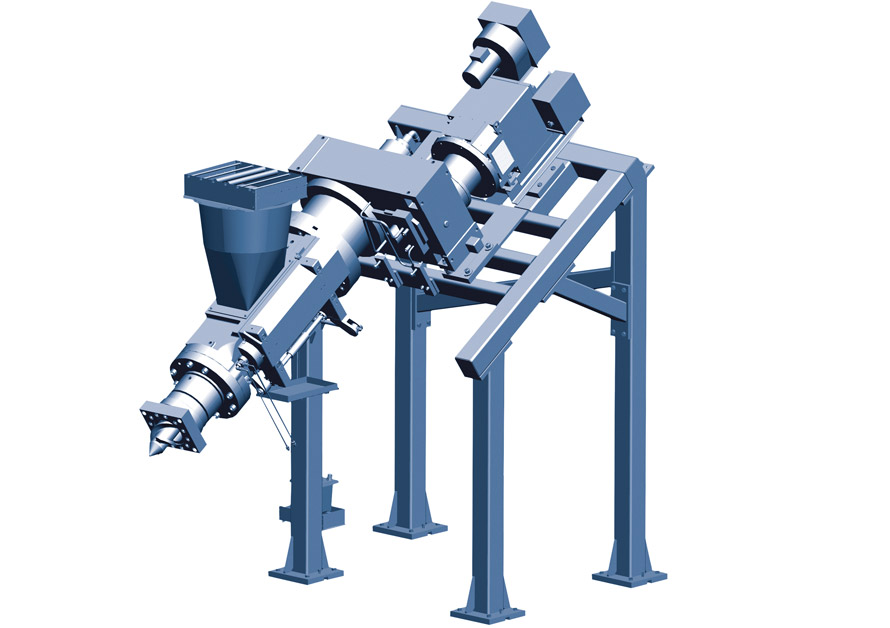

The trend in the tire industry is headed towards using increasingly high viscous natural rubber compounds for special applications such as truck tread. Due to their limits concerning temperature and homogeneity, standard cold feed extruders cannot process these hard natural rubber compounds efficiently.

From an economic point of view, hot feed extruders can run these special applications more efficiently, even when taking initial investment costs for peripheral equipment and the higher operating costs into account.

Our hot feed portfolio is aimed at high output rates with these particularly high viscous compounds. We offer screw diameters of 200 mm and 250 mm.

HF TireTech Group

Service Extrusion

Tel.: +49 40 77179-649

Fax: +49 40 77179-407